The history of the PLC

PLCS originated in the late 1960s in the US automotive industry to replace relay logic systems. Compared with earlier automation systems, PLCS have many advantages. It can withstand industrial environments better than computers, and is more reliable, compact and requires less maintenance than relay systems. It can be easily extended with additional I/O modules, whereas relaying systems require complex hardware changes in case of reconfiguration. This simplifies iteration in the design of the manufacturing process. With a simple programming language that emphasizes logic and switching operations, it is more user-friendly than computers using general-purpose programming languages. It also allows monitoring of its operations. Early PLCS were programmed with trapezoidal logic, which is very similar to the schematic diagram of relay logic. This programming approach was chosen to reduce the need for training existing technical staff. There are also PLCS that use instruction lists.

Schneider electric Modicon

In 1968, GM Hydramatic (General Motors' automatic transmission division), based on a white paper written by engineer Edward R. Clark, issued a request for proposals for an electronic replacement for hard-wired relay systems. The winning proposal is from the Bedford Society in Bedford, Massachusetts. It turned out that the first PLC (built in 1969) was named 084 because it was Bedford Associates' eighty-fourth project.

The Belford Institute created a company dedicated to developing, manufacturing, marketing and servicing the new product, which they named Modicon (for Modular Digital Controller). One of the people working on the project was Dick Morley, considered the "father" of PLC. The Modicon brand was sold to Gould Electronics in 1977 and later to the current owner Schneider Electric. One of the first 084 models is now on display at Schneider Electric's plant in North Andover, Mass.

Gm offered it to Modicon after retiring it after nearly 20 years of uninterrupted service. Modicon used the name 84 at the end of its product line until 984 appeared.

Allen-Bradley

In parallel development, Odo Josef Struger is also sometimes referred to as the "father of the programmable Logic controller". He was involved in the invention of the Allen-Bradley programmable Logic Controller between 1958 and 1960 and is credited with inventing the abbreviation PLC. During his tenure, Allen-Bradley, now a brand name of Rockwell Automation, became a major manufacturer of PLCS in the United States. Struger played a leading role in the development of the IEC 61131-3 PLC programming language standard.

Early programming methods

Many early PLCS could not be represented graphically in a logical way, so it was represented as a series of logical expressions in some Boolean format, similar to a Boolean algebra. With the development of programming terminals, trapezoidal logic became more and more common as it was the common format for electromechanical control panels. Newer formats exist, such as state logic and functional blocks (similar to the way logic is described when using digital integrated logic circuits), but they are still not as popular as ladder logic. The main reason is that PLCS execute logic in a predictable and repetitive order, and ladder logic makes it easier for those who write logic to see the timing of logical sequences.

Until the mid-1990s, PLCS were programmed using proprietary programming panels or dedicated programming terminals, often with dedicated function keys that represent the various logic elements of a PLC program. Some proprietary programming terminals display elements of PLC programs as graphical symbols, but plain ASCII character representations of contacts, coils, and wires are common. The program is stored on a cassette tape. Due to the lack of storage capacity, there are few facilities for printing and documentation. The oldest PLCS use non-volatile core memory.

The PLC architecture

PLC is a controller based on industrial microprocessor with programmable memory for storing program instructions and various functions. It includes:

1. Processor unit (CPU), which interprets input, executes control programs stored in memory, and sends output signals

2. The power supply unit that converts AC voltage into DC

3. Storage unit, which stores data from the input and programs executed by the processor

4. Input and output interfaces where the controller receives and sends data from external devices

5. A communication interface for receiving and transmitting data from and to the remote PLC over the communication network.

6.PLC needs programming equipment, which is used to develop and subsequently download the created program to the controller's memory

Mechanical design

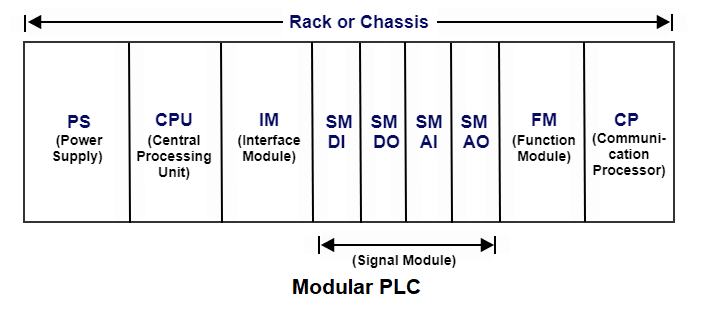

There are two types of mechanical design for PLC systems. A single box acts as a small programmable controller to fit all units and interfaces into a compact housing, although often additional expansion modules for input and output are available. The second design type - modular PLCS - has chassis (also known as racks) that provide space for modules with different functions (such as power supply, processor, I/O module selection and communication interfaces) - all tailored to specific applications. A single processor can manage multiple racks and may have thousands of inputs and outputs. Special high-speed serial I/O links or similar communication methods can be used so that racks can be distributed away from processors, reducing wiring costs for large plants. Optionally, I/O points can be mounted directly to the machine and connected to sensors and valves using quick disconnect cables, saving wiring and component replacement time.

Discrete and analog signals

Discrete (digital) signals can only take values (1 or 0, yes or no). Examples of devices that provide discrete signals include limit switches, photoelectric sensors, and encoders. Discrete signals are sent using voltages or currents, where specific extreme ranges are specified as on and off. For example, a controller might use a 24 V DC input, with values above 22 V DC indicating switched on and values below 2 V DC indicating disconnected, with an undefined intermediate value. The analog signal may use a voltage or current proportional to the size of the monitored variable and may take any value within its range. Pressure, temperature, flow rate and weight are usually represented by analog signals. Depending on the device and the number of bits available to store the data, they are often interpreted as integer values with various ranges of accuracy. For example, analog quantities 0 to 10 V or 4 to 20 mA inputs are converted to integer values from 0 to 32,767. The PLC will take the value and convert it to the desired process unit so that an operator or program can read it. Proper integration will also include filtering times to reduce noise, and upper and lower limits for reporting faults. Current inputs are less sensitive to electrical noise, such as noise from welders or motor starts, than voltage inputs. Distance from the device and controller is also an issue, as the maximum travel distance for high-quality 0-10V signals is very short compared to 4-20 mA signals. The 4-20 mA signal can also report if the wire is disconnected along the path, as it will return a 0 mA signal.

redundant

Some special processes need to run permanently to reduce unnecessary downtime. Therefore, it is necessary to design a fault-tolerant system that can handle processes with faulty modules. In this case, if a hardware component fails, you can add redundant cpus or I/O modules with the same functions to the hardware configuration to prevent all or part of the processes from shutting down due to a hardware fault, thereby improving system reliability. Other redundancy schemes may relate to processes that are critical to safety, for example, a large hydraulic press may require both PLCS to open one output before the press descends in case one output does not close properly.

programming

PLC target users are engineers without programming background. For this reason, a graphical programming language called LD (Ladder Diagram) was first developed. Because it and the traditional relay logic circuit schematic diagram is very similar, so it is used by many manufacturers, and later was added to the IEC61131-3 standard. Because of its simplicity, it was still widely used until 2015.

Until 2015, most PLC systems will follow the IEC61131-3 standard, which defines two textual programming languages: ST (structured text, similar to Pascal) and IL (instruction list); Three graphical programming languages: LD (ladder diagram), FBD (function Block diagram), and SFC (Sequential Function diagram). IL was deprecated in the third version of the standard.

Modern PLCS can be programmed in a variety of ways, from LD languages derived from relay logic to specially adapted general-purpose computer programming languages such as BASIC and C.

Although the basic concepts of PLCS are the same for all manufacturers, differences in I/O addressing, storage organization, and instruction sets make PLC programs difficult to generalize across PLCS from different manufacturers. Even from the same manufacturer, different PLC kits may not be compatible.

PLC programming equipment

PLC programs are usually developed in programming equipment, programming equipment can be desktop console, desktop graphics software, or handheld programming equipment. The program is then downloaded to the PLC either directly or over the network. It is stored either in a RAM with a power supply or in a non-volatile storage device. In some PLCS, programs are burned from a personal computer to a removable chip via a programming board, such as an EPROM.

Manufacturers develop programming software for their controllers. In addition to being able to program PLCS in a variety of programming languages, they also provide generic features such as hardware diagnostics and maintenance, software debugging, and offline simulation.

A program developed on a PC or uploaded from a PLC can easily be copied and stored to an external device.

The simulation

PLC simulation is usually one of the functions of PLC programming software. It allows engineers to test and debug programs early in project development.

Incorrect PLC procedures can lead to low production efficiency and dangerous accidents. Testing the project in the simulation environment improves its reliability and reduces the project cost and cycle time.

Function

PLC and other computing equipment is different in its strong tolerance to harsh environment (dust, humidity, high temperature, low temperature, electromagnetic interference), while providing extended I/O to connect PLC and other sensors, drivers. Inputs to a PLC can include simple digital quantities, such as limit switches, analog quantities from a process (such as temperature and pressure), and more complex data, such as position and machine vision systems. PLC outputs may include indicators, alarms, motors, pneumatic or hydraulic cylinders, magnetic relays, solenoses or analog outputs, and other elements. The input/output device can be built into a simple PLC, or the PLC can have an external I/O module connected to a fieldbus or computer network plugged into the PLC.

PLC function after years of development, has included sequential relay control, motion control, process control, discrete control and network control. The data processing, storage, power consumption and communication capabilities of some modern PLCS are comparable to those of desktop computers. There are also applications that use general-purpose computers as controllers. But this kind of controller is not widely accepted in heavy industry, because compared with PLC, desktop computer runs on the operating system is not very stable, and desktop computer hardware to the harsh environment (high and low temperature, humidity, vibration, etc.) tolerance is very limited. In operating systems such as Windows, the program execution time is uncertain, so the controller may not execute the instructions according to our pre-designed timing. This general purpose computer based controller is generally used in some environment requirements are not very high, such as laboratory.

The basic function

The most basic function of PLC is to simulate electromechanical relay system. Discrete inputs are given a special address, and PLC instructions can test the status of the input. A series of relay contacts perform logic and operations, and no current is allowed to pass through unless all contacts are closed, so a series of "if on" commands excite the output to be on if all inputs are on.

Some PLCS enforce a left - to - right, top - to - bottom order. This is not the same as hard-wired relay systems. In some sufficiently complex relay systems, the current may flow from left to right or right to left, depending on the configuration of the surrounding contacts. This quirk can be a bug or a feature, depending on how you program.

More advanced PLC instructions may be implemented as functional blocks.

PLC communication

The PLC uses built-in ports such as USB, Ethernet, RS-232, RS485,RS422 to connect with external devices (sensors, drivers) and systems (programming software, SCADA, HMI). Communication functions rely on various industrial network protocols, such as Modbus, Profibus, ProfiNet. Many protocols are specific to PLC manufacturers.

PLCS used in large-scale I/O systems may have peer-to-peer (P2P) communication between processors. This allows individual parts of a complex process to be relatively autonomously controlled and coordinated with each other through communication links. These communication links are usually used for HMI devices or PC-type workstations.

The user interface

PLC may need to interact with personnel for configuration, alarm and daily monitoring purposes. HMI is designed for this purpose. HMI interfaces are also called man-machine interfaces (MMI) or GUI. A simple system would use buttons and lights to interact with the user. Textual display and graphical touch screen are also available. More complex systems use programming and monitoring software installed on general-purpose computers.

Scan cycle process

The PLC is repeated in the program scan cycle. The simplest scan cycle consists of three steps:

1. Read the input

2. Execute the program

3. Write output

The program is executed sequentially, one by one, and usually the execution time is fixed, but if there are some remote I/O devices, then the time consumed by communication may be introduced into the PLC system.

As PLC becomes more and more advanced, some methods have been developed to change the execution order of ladder diagram. This enhanced programming method can be used to save the scanning time of high-speed process. For example, the initialization part of a program can be separated from the parts that require high-speed execution. The updated PLC supports simultaneous execution of program execution and I/O scan. This means that I/O data is updated in the background and logical reads and writes are performed during logical scans.

When PLC scanning time is too long, some special I/O modules can be used to achieve predictable performance. When the scanning period is too long, PLC can not accurately detect the rotation pulse, then can use accurate time module, or counting module. This allows a rather slow PLC to still interpret the count correctly and control the machine.

Security

In his 1998 book, E.A.Purr notes that while most programmable controllers require physical buttons and passwords, strict access control and version control systems, and the absence of an easy-to-understand programming language make illegal changes to programs possible and difficult to detect.

Before the Stuxnet computer worm, little attention was paid to PLC security. Modern programmable logic controllers typically include a real-time operating system that may face the same risks as a normal desktop operating system. The PLC can also be attacked by attacking the computer connected to the PLC. Since 2011, with PLC gradually access to the office network, PLC security issues are increasingly concerned.

Safety PLC

In recent years, "secure" PLCS have become popular, either as stand-alone models or as functional and safe-level hardware added to existing controller architectures (Allen-Bradley Guardlogix, Siemens F series, etc.). They differ from traditional PLC types in that they are suitable for safety-critical applications where the PLC has traditionally been added with hard-wired safety relays and a memory area dedicated to safety instructions. The standard for security level is SIL. For example, a safety PLC might be used to control access to a robot unit with trap key access, or it might be used to manage the shutdown response to an emergency stop on a conveyor production line. Such PLCS typically have restricted regular instruction sets with added safety-specific instructions that are designed to interface with emergency stops, light screens, etc. The flexibility provided by such systems has led to a rapid increase in the demand for these controllers.

PLC compared with other control systems

PLC is very suitable for various automation tasks. These are typically industrial processes in manufacturing where the cost of developing and maintaining an automated system is high relative to the total cost of automation, and changes may be made to the system throughout its useful life. PLC contains input and output equipment compatible with industrial pilot equipment and controls; Little electrical design is required, and the design problem focuses on expressing the desired sequence of operations. PLC applications are typically highly customized systems, so packaged PLCS have a lower cost compared to specific custom controller designs. On the other hand, for mass-produced goods, customized control systems are economical. This is due to the lower cost of components, the ability to choose the best component over a "generic" solution, and the spread of non-recurring engineering expenses over thousands or millions of units. Programmable controllers are widely used in motion, positioning and torque control. Some manufacturers produce motion control units that will be integrated with a PLC so that a G-code (involving CNC machine tools) can be used to indicate machine motion.

PLC chip/embedded controller

For some small or medium sized machines. PLCS that can execute languages such as ladder diagram languages are similar to traditional PLCS, but their small size allows developers to design them into custom printed circuit boards, like a microcontroller. It is a kind of industrial controller between classical PLC and microcontroller.

CAM timer

For automated tasks with large volumes and very fixed functions, other counts can be used. For example, an inexpensive consumer-grade dishwasher may only require an inexpensive electromechanical CAM timer.

Micro controller

Microcontroller-based designs will be suitable for situations where hundreds or thousands of units will be produced, so development costs (power supply, design of input/output hardware, and necessary testing and certification) can be spread over many sales without the end user having to change the controls. Car apps are an example. Millions of units are built each year, and very few end users change the programming of these controllers. However, some special purpose vehicles, such as buses, are economical to use PLCS rather than custom-designed controls because of their small size and uneconomical development costs.

Single board computer

Very complex process controls, such as those used in the chemical industry, may require algorithms and performance that are beyond the capabilities of even high performance PLCS. High-speed or precision controls may also require customized solutions. For example, flight control of aircraft. For demanding control applications, single-board computers with semi-custom or fully proprietary hardware can be selected, where high development and maintenance costs can be supported. A "soft PLC" running on a desktop computer can interface with industrial I/O hardware while executing programs in a commercial version of the operating system suited to process control requirements.

The increasing popularity of single board computers has also had an impact on the development of PLC. Traditional PLCS are usually closed platforms, but some newer PLCS (such as Bosch Rexroth's ctrlX, Wago's PFC200, Phoenix Contact's PLCnext and Kunbus's Revolution Pi) offer traditional PLCS on open platforms.

The PID controller

PLCS may include logic for univariate feedback simulation control loops, PID controllers. For example, PID loops can be used to control the temperature of the manufacturing process. Historically, PLCS were usually configured with only a few analog control loops. If the process requires hundreds or thousands of cycles, a distributed control system (DCS) will be used. As PLCS have become more powerful, the line between DCS and PLC applications has blurred.

Programmable logic Relay (PLR)

In recent years, small products called programmable logic relays (PLR) or intelligent relays have become more common and accepted. These, similar to PLCS, are used in light industry, require only a few I/O points, and require low cost. These small devices are usually manufactured by several manufacturers in the same physical size and shape, and are trademarked by the manufacturer of the large PLCS to fill their low-end product range. Most of them have 8 to 12 discrete inputs, 4 to 8 discrete outputs, and up to 2 analog inputs. Most of these devices including small LCD screen, the size of a postage stamp for viewing a simplified trapezoidal logic (at a given time only a small part of the display program) and the condition of the I/O points, these screens are usually accompanied by a 4 to the joystick buttons, plus four separate button, similar to the VCR button on the remote control, is used for navigation and edit the logic. Most tools have a small plug for connecting to a personal computer via RS-232 or RS-485 so that programmers can program using simple Windows applications without having to use a tiny LCD and button setup for this purpose. Unlike regular PLCS, which are typically modular and extensible, PLRS are typically not modular or extensible, but can cost up to two orders of magnitude less than PLCS, and they still provide reliable design and deterministic logic execution.

A variant of PLC used at remote locations is the remote Terminal Unit or RTU. An RTU is typically a low-power, rugged PLC whose key function is to manage the communication link between a site and a central control system (usually SCADA) or "cloud" in some modern systems. Unlike factory automation, which uses high-speed Ethernet, communication links to remote sites are usually radio based and less reliable. To address the reduced reliability, RTU buffers messages or switches to alternate communication paths. When buffering messages, RTU timestamps each message so that a complete history of site events can be reconstructed. RTU is PLC, with a wide range of I/O, and can be fully programmed, usually using many PLC, RTU and DCS common IEC 61131-3 standard language. In remote areas, it is common to use the RTU as a gateway to a PLC, where the PLC performs all site control and the RTU manages communications, timestamps events and monitors ancillary devices. On sites with little I/O, the RTU can also be a site PLC and can perform communication and control functions.

PLC manufacturers

Top manufacturers of programmable logic controllers include:

1.ABB is a Swedish-Swiss multinational company engaged in automation technology and robotics

2. B&R Industrial Automation is an Austrian PLC manufacturer, part of ABB Group since 2017

3.Bosch Rexroth is a German company dedicated to drive and control technology, including industrial control

4.Emerson Electric is an American company that manufactures products and provides engineering services for industrial markets

5.General Electric Company is a multinational company providing technology and service business, headquartered in Boston, USA.

6. Honeywell is an American company in the high-performance materials and technology industry.

7. Mitsubishi Electric, a Japanese electronics and electrical equipment manufacturing company, has Melsec PLC series

8.Rockwell Automation is an American company that took over Allen-Bradley's PLC giant enterprise

9.Siemens, a German multinational group, is committed to the development of Simatic S7 PLC series.

10.Schneider Electric is a French electrical equipment company that owns the original Modicon PLC brand.

More...