.Many products are not yet on the shelves please contact us for more products

.If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

.We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

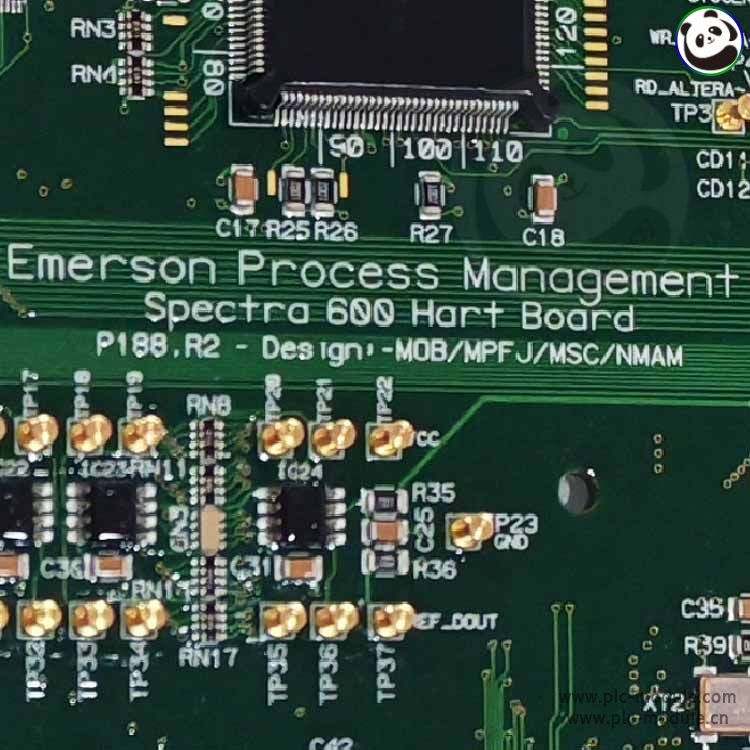

The Emerson Spectra 600 HART Board P188.R2 PCB is a specialized printed circuit board (PCB) designed for use in Emerson's Spectra 600 series power systems. This board is specifically tailored to support the HART (Highway Addressable Remote Transducer) communication protocol, which is widely used in industrial automation and process control systems.

Emerson Process Managemen+

Spectra 600 Hart Board

P188.R2 - Design -MOB/MPF J/MSC/NMAM

Key Features of the Emerson P188.R2 HART Communication Circuit Board:

HART Protocol Support:

The HART protocol allows for digital communication over traditional 4-20 mA analog signals, enabling two-way communication with smart field devices.

It supports device configuration, diagnostics, and real-time data retrieval.

Functionality:

Signal Conditioning: Converts and processes analog and digital signals from HART devices.

Communication Interface: Acts as a bridge between HART devices and the control system.

Diagnostics: Provides access to diagnostic data from field devices for predictive maintenance and troubleshooting.

Design:

The PCB is designed for industrial environments, with robust components to withstand harsh conditions such as temperature variations, humidity, and vibrations.

It may include components like microcontrollers, HART modems, signal isolators, and communication interfaces.

Integration:

Common Applications:

Process Automation: Used in industries like oil and gas, chemical, and manufacturing to integrate HART devices into control systems.

Remote Monitoring: Enables remote configuration and monitoring of field devices.

Diagnostics and Maintenance: Facilitates access to device health and performance data for predictive maintenance.

YOU MAY ALSO NEED TO KNOW: