.Many products are not yet on the shelves please contact us for more products

.If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

.We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

GE RS-FS-9001 362A1052P104 Flame Detector.

The GE RS-FS-9001 362A1052P104 is a flame detector designed for industrial fire detection and safety systems. Flame detectors are critical in environments where rapid fire detection is essential, such as in oil and gas facilities, power plants, and chemical processing plants.

Key Features:

Flame Detection Technology:

Utilizes advanced optical sensors to detect flames, typically by sensing ultraviolet (UV) and/or infrared (IR) radiation emitted by flames.

Capable of detecting hydrocarbon-based fires (e.g., oil, gas, and solvents) and non-hydrocarbon fires.

High Sensitivity:

Wide Coverage:

Robust Construction:

Built to withstand harsh industrial environments, including exposure to dust, moisture, and extreme temperatures.

Compliance:

Meets industry standards for flame detection and safety systems, such as UL, FM, and ATEX certifications (depending on the model and region).

Integration:

Applications:

Oil and gas facilities (refineries, pipelines, offshore platforms).

Power generation plants.

Chemical and petrochemical plants.

Aircraft hangars and military facilities.

Warehouses and storage facilities with flammable materials.

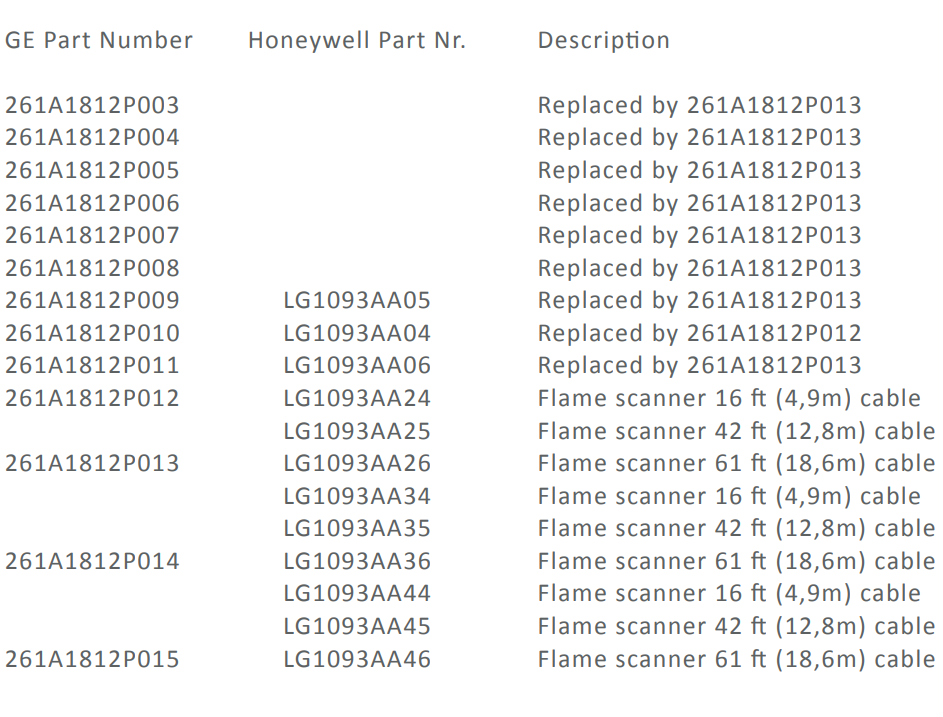

FLAME DETECTOR FAMILY

The flame scanner is an important and integral part of safety systems for industrial heavy duty gas turbine operation. It is one of the most expensive consumable parts on which the reliable operation of a gas turbine depends.

One of its main tasks is to detect potentially dangerous "flame off" situations which occur in the event of an ignition failure. If unchecked, the supply of fuel is continually fed during "flame off" event. The results could be catastrophic, in worse case scenarios leading to an explosion, putting the safety of operators at risk or causing damage to property and equipment. Therefore, the monitoring of the flame is vital for a safe working environment, particularly during at the start-up or shut-down procedures of the gas turbine.

Replace Honeywell