BENTLY NEVADA

Bently Nevada (Bently)

It was founded in the 1950s in Minden, Nevada

Global leader in equipment condition monitoring

He joined the GE family in 2002

Bently Nevada is a condition monitoring instrumentation company, providing services for sensors, systems, and monitoring machinery vibration.

The offerings are primarily intended for assessing the mechanical condition of rotating equipment found in machinery-intensive industries such as oil and gas production, hydrocarbon processing, electric power generation, pulp & paper, water and wastewater treatment, mining, and the like.

Bently Nevada was a privately held US corporation between 1961 and 2002, during which time it pioneered the eddy-current proximity probe, a sensor that revolutionized the measurement of vibration in high-speed turbomachinery by allowing the direct observation of the rotating shaft. The company also performed significant research in the field of rotordynamics, furthering knowledge of machinery malfunctions such as shaft cracks and fluid-induced instabilities. Its research also helped refine the equations used to describe vibratory behavior in rotordynamic systems.

The company was acquired by GE Energy in February, 2002, and continues to design, manufacture, and market these products and services using the Bently Nevada name.

Now, Bently Nevada was belong to GE Measurement & Control (Formerly GE Sensing). And we can supply all kind of products from Bently Nevada.

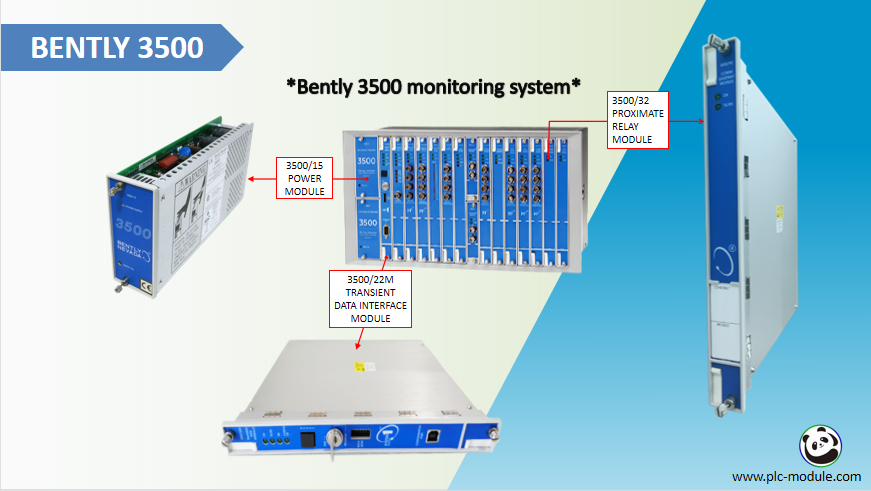

Bently Nevada: 3500/3300 system, Proximitor probe, etc., e.g. 3500/22,3500/32, 3500/20

BENTLY NEVADA 3500/15 POWER MODULE

BENTLY NEVADA 3500/22 TRANSIENT DATA INTERFACE I/O MODULE

Bentley 3500/22M Transient Data Interface Product Description:

The 3500/22M Transient Data Interface (TDI) is the interface between the 3500/22M monitoring System and Bentley Nevada System 1TM mechanical management software. Common models: 3500/22-01-01-00, 3500/22-01-01-01

The 3500/22M Transient Data Interface (TDI) is the interface between the 3500 monitoring System and the Bentley Nevada System 1TM mechanical management software. TDI combines the capabilities of a 3500/20 framework interface module (RIM) with a communication processor such as TDXnet.

The TDI operates in a RIM slot in a 3500/22M frame and is used in conjunction with M-series monitors (3500/40M, 3500/42M, etc.) to continuously collect steady and transient waveform data and transmit the data to the main computer software via Ethernet.

TDI has standard static data collection, but with optional channel enabled disks, transient or dynamic data can also be collected.

TDI has several improvements over previous communication processors, in addition to integrating communication processor capabilities into the 3500 framework. TDI provides generic functionality to the framework, but is not an integral part of the critical monitoring channel and does not affect the correct and routine operation of the overall monitoring system. Each framework requires a TDI or RIM. The TDI occupies only one slot in the frame and must be located in a slot next to the power module.

For Triple Module redundancy (TMR) applications, the 3500 system requires TDI in the form of TMR. In addition to the functionality of the standard TDI, the TMR TDI also has a "monitor channel comparison feature".

The 3500TMR configuration performs the monitor voting function by selecting the install function of the MONITOR option. In this way, the TMR TDI continuously compares the output of the three redundant monitors. If the TMR TDI detects that the output of one monitor is not equal to the output of the other two monitors (within a percentage of the configuration), it issues an error indication to the monitor.