.Many products are not yet on the shelves please contact us for more products

.If there is any inconsistency between the product model and the picture on display, the model shall prevail. Contact us for the specific product picture, and we will arrange to take photos in the warehouse for confirmation

.We have 16 shared warehouses around the world, so please understand that it can sometimes take several hours to accurately return to you. Of course, we will respond to your concerns as soon as possible

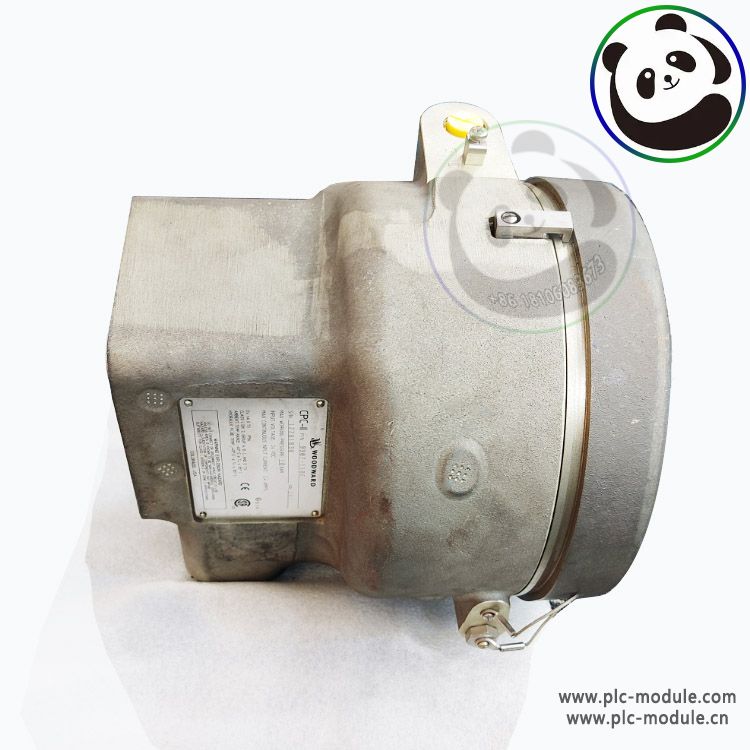

WOODWARD CPC 9907-1106 Current Pressure Converter CPC-II.

The Woodward CPC-II (Current-to-Pressure Converter, Generation II) is an electrohydraulic pressure-regulating valve control designed specifically for positioning single-acting steam turbine valve servos. It is engineered to offer superior accuracy and resolution, making it highly suitable for controlling steam turbine valves and associated turbine speed and load control. The CPC-II operates by accepting a 4–20 mA pressure demand signal and then accurately regulating oil pressure to precisely position the single-acting steam turbine governor-valves. This precise and stable control of steam valves contributes to enhanced steam turbine speed and load control, alongside minimizing system mechanical wear.

DOWNLOAD:

CPCII 9907-1106 .pdf

CPCII 9907-1106 .pdf

One of the key features of the CPC-II is its robust design, which includes a strong actuator, corrosion-resistant materials, a single moving rotary valve, and a self-cleaning port design. This design is particularly advantageous in environments where the oil may be dirty or contaminated. Additionally, the CPC-II supports redundancy configurations, allowing it to accept redundant pressure demand inputs from one or two controllers and vote the input to follow. It can also integrate both its internal oil pressure sensor and an external (redundant) oil pressure sensor, utilizing the voted healthy signal for operation. This redundancy feature is crucial for critical steam turbine applications where maintaining turbine uptime and availability is paramount.

The CPC-II incorporates a very accurate internal pressure sensor and a PID controller within its valve-actuator assembly, pressure sensor, and electronic driver module setup. This configuration enables the CPC-II to compare the received pressure setpoints against the sensed oil pressure, thereby achieving precise control of turbine valve oil pressure. The system is designed to maintain stable pressure control under normal conditions and respond swiftly to desired valve step changes during system or plant transients. Furthermore, the CPC-II employs an internal valve-return-spring mechanism to ensure a failsafe position in case of any internal unit failure, such as electrical input power failure, pressure sensor failure, or processor failure, thereby safeguarding the turbine.

The CPC-II is part of Woodward's initiative to address the steam turbine market's primary reliability issue, which is oil contamination. It is equipped with 'dirt buster' technology capable of powering through 40 µm sized dirt particles, significantly reducing or even eliminating the need for turbine control filter servicing. This technology, along with patent-pending 'Silt Buster' cleaning technology, ensures clear silt build-up without disrupting operational integrity. The CPC-II also boasts industry-leading stability and bumpless precision throttle valve control, offering enhanced functionality and maximum operating efficiency advantages.

WOODWARD CPC 9907-1106 Current Pressure Converter CPC-II