DCS, PLC, FCS three systems comparison

PREFACE

In some industries,FCS is developed from PLC;In other industries,FCS is developed from DCS,so there are countless links and essential differences between FCS and PLC and DCS.

DCS, PLC, FCS three systems comparison

ANSWER

PLC, DCS, and FCS are three major control systems used in industrial process control. PLC stands for Programmable Logic Controller, DCS stands for Distributed Control System, and FCS stands for Field Control System. Each system has its own unique characteristics and is designed for different purposes. In this answer, we will explore the differences between these three systems and their pros and cons.

PLC is a digital electronic system designed specifically for industrial applications. It uses a programmable memory to store programs and execute logical operations, sequential control, timing, counting, and arithmetic operations. PLC has many functions, including data processing, communication, and networking. It can be used as a standalone system or as a subsystem of DCS. PLC is suitable for sequential control in industrial processes and has a low cost. However, it is not suitable for large-scale control systems and lacks the ability to handle complex processes. [1]

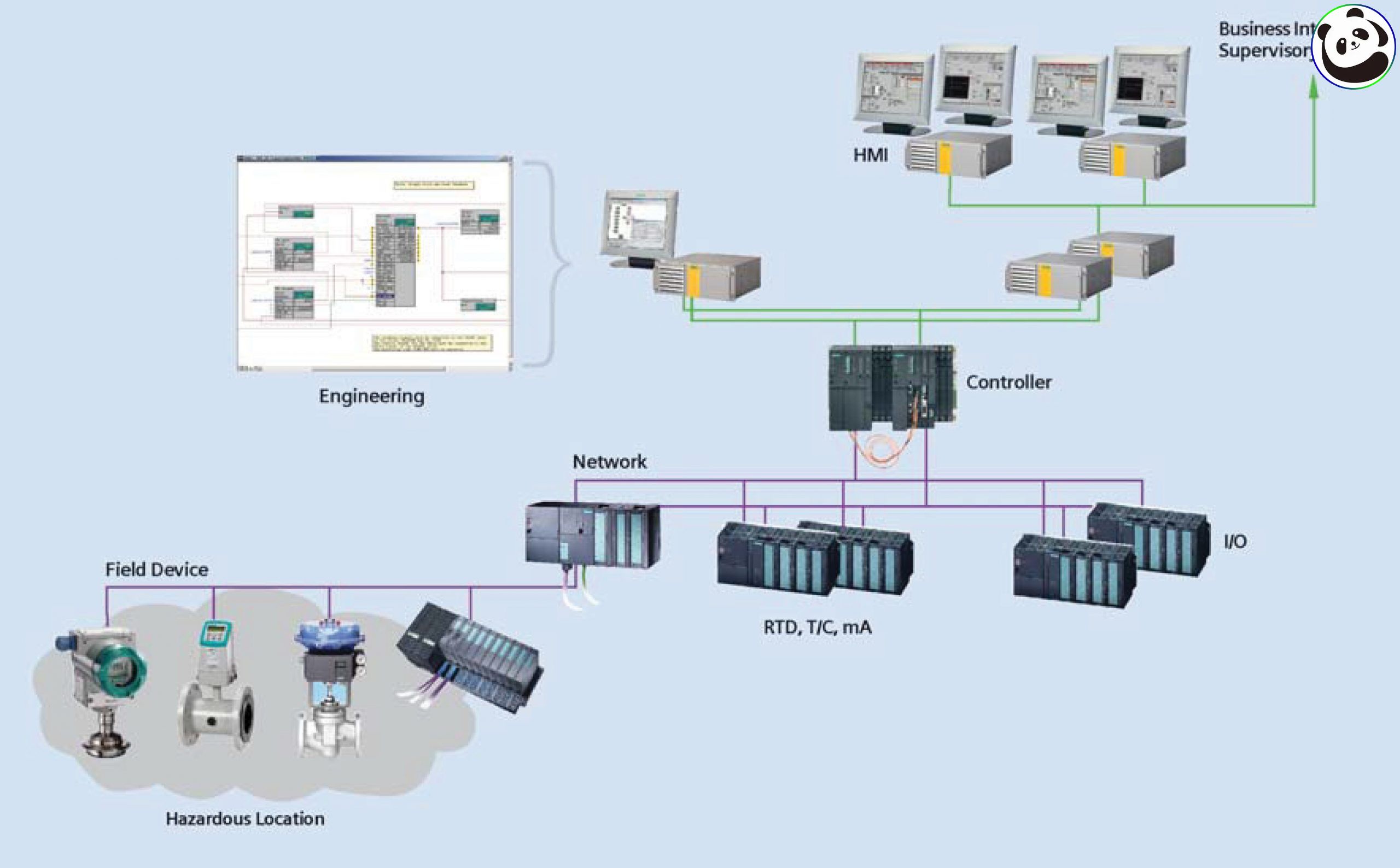

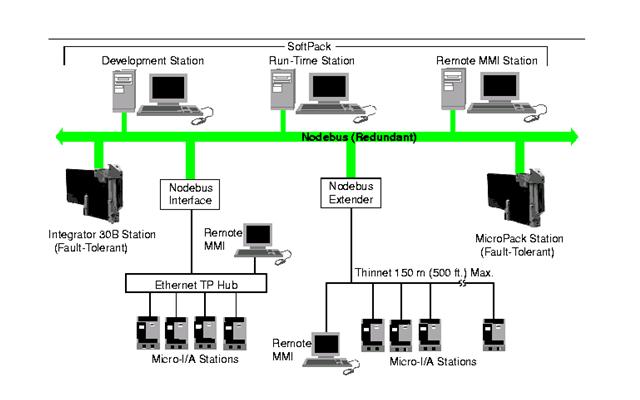

DCS is a distributed control system that combines communication, computer, control, and CRT technologies into a single monitoring technology. It has a tree-like topology structure with communication being the key. DCS is suitable for large-scale control systems, has a high level of intelligence, and can handle complex processes. It has a high level of security and reliability due to its redundant control units. However, DCS is expensive and requires a high level of expertise to operate. [0]

FCS is a fusion of 3C (Computer, Communication, and Control) technologies. It is suitable for essential safety, hazardous areas, variable processes, and difficult environments. FCS has a high level of intelligence and provides full digital signals. It uses a single bus to connect all devices and has a parallel continuous chain structure with a large number of cables from the relay station to the field instrument. FCS is suitable for small-scale control systems and has a low cost. However, it is not suitable for large-scale control systems and lacks the ability to handle complex processes

BASIC CHARACTERISTICS OF PLC,DCS AND FCS CONTROL SYSTEMS

At present,there are three major control systems in continuous process automatic production control(PA)or industry process control,namely PLC,DCS and FCS.Their basic characteristics are as follows:

PLC

(1)From switch control to sequence control and transportation processing,it is from bottom to top.

(2)Multi functions such as continuous PID control,and PID is in the interrupt station.

(3)One PC can be used as the master station and multiple PLCs of the same type can be used as slave stations.

(4)One PLC can also be used as the master station and multiple PLCs of the same type can be used as slave stations to form a PLC network.This is more convenient than using a PC as the master station:when there is user programming,you don't need to know the communication protocol,just write it in the format of the manual.

(5)The PLC grid can be used either as an independent DCS/TDCS or as a subsystem of DCS/TDCS.

(6)The large system is the same as DCS/TDCS,such as TDC3000,CENTUMCS,WDPFI and MOD300.

(7)PLC networks such as Siemens'SINEC-L1,SINEC-H1,S4,S5,S6,S7,etc.,GE's GENET,Mitsubishi's MELSEC-NET,MELSEC-NET/MINI.

(8)It is mainly used for sequence control in industrial processes.The new PLC also has the function of closed-loop control.

(9)Manufacturer:GOULD,AB,GE,OMRON,MITSUBISHI,Siemens,etc.

DCS or TDCS

(1)Distributed control system(DCS)and distributed control system(TDCS)are monitoring technologies integrating 4C(Communication,Computer,Control,CRT)technologies.

(2)In the top-down tree topology large system,communication is the key.

(3)PID is in the interrupt station,and the interrupt station connects the computer with the field instruments and control devices.

(4)It is a tree topology and a parallel and continuous link structure.There are also a large number of cables from the relay station to the field instruments in parallel.

(5)Analog signal,A/D-D/A,mixed with microprocessor.

(6)A pair of wires of one instrument are connected to the I/O and connected to the LAN by the control station.

(7)DCS is a three-level structure of control(engineer station),operation(operator station)and field instrument(field measurement and control station).

(8)The disadvantage is that the cost is high,the products of various companies cannot be exchanged and interoperable,and the large DCS systems are different from each other.

(9)It is used for large-scale continuous process control,such as petrochemical,etc.

(10)Manufacturer:Bailey(US),Westinghouse(US),HITACH(Japan),LEEDS&NORTHRMP(US),SIEMENS(Germany),Foxboro(US),ABB(Switzerland),Hartmann&Braun(Germany),Yokogawa(Japan),Honeyell(US),Taylor(US),etc.

FCS

(1)The basic tasks are:intrinsically safe,dangerous areas,volatile processes,and difficult to deal with unusual environments.

(2)All digital,intelligent and multi-functional analog single function instruments,meters and control devices are replaced.

(3)Two lines are used to connect decentralized field instruments,control devices,PID and control center,replacing two lines for each instrument.

(4)On the bus,PID is equal to instruments,meters and control devices.

(5)Multi variable,multi node,serial and digital communication systems replace single variable,single point,parallel and analog systems.

(6)It is interconnected,two-way and open to replace one-way and closed.

(7)Replace centralized control stations with decentralized virtual control stations.

(8)Operated by the field computer,it can also be connected to the upper computer and connected to the upper computer of the same bus.

(9)The LAN can be connected to the Internet.

(10)Change the traditional signal standards,communication standards and system standards into the enterprise management network.

(11)Manufacturers:Honeywell,Smar,Fisher Rosemount,AB/Rockwell,Elsag Bailey,Foxboro,Yamatake,Yokogawa,Siemens,GEC Alsthom,Schneider,process Data,ABB,etc.

(12)Typical of Category 3 FCS

1)Continuous process automatic control,such as petrochemical industry,in which"intrinsically safe explosion-proof"technology is absolutely important,typical products are FF,World FIP,Profibus PA;

2)Discrete process action automatic control,such as automobile manufacturing robot and automobile,typical products are Profibus DP and CANbus;

3)For multi-point control,such as building automation,typical products are LON Work and Profibus FMS.

From the description of the above basic points,do we notice that none of the three systems used for process control is developed for the power station,or that in the early stage of their development,the power station is not the preferred control object of the system.In the instructions for the use of these systems,the power station is never the preferred scope of application,and some do not mention the power station at all.Now it is strange that these three control systems,especially DCS and PLC,have been widely used in power plants,and the effect is very good.

3.Differences among the three control systems

As we know,FCS is developed from DCS and PLC.FCS not only has the characteristics of DCS and PLC,but also has taken a revolutionary step.At present,the new DCS and the new PLC have a tendency to move closer to each other.The new DCS has strong sequence control function;The new PLC is not bad at dealing with closed-loop control,and both can form a large network.The scope of application of DCS and PLC has greatly crossed.The next section compares DCS with FCS only.In the previous chapters,the differences between DCS and FCS have actually been involved.The following will describe the architecture,investment,design,use,www.plc-module.com etc.

DIFFERENCES

DCS

The key of DCS system is communication.It can also be said that data highway is the backbone of DCS.Because its task is to provide a communication network between all parts of the system,the design of the data highway itself determines the overall flexibility and security.The media of data highway can be a pair of twisted wires,coaxial cables or optical fiber cables.

Through the design parameters of data highway,we can basically understand the relative advantages and disadvantages of a specific DCS system.

(1)How much I/O information can the system handle.

(2)How much control loop information related to control can the system handle.

(3)How many users and devices can be adapted(CRT,control station,etc.).

(4)How to thoroughly check the integrity of the transmitted data.

(5)What is the maximum allowable length of the data highway.

(6)How many branches can the data highway support.

(7)Whether the data highway can support the hardware(programmable controller,computer,data recording device,etc.)produced by other manufacturers.

To ensure the integrity of communication,most DCS manufacturers can provide redundant data highways.

In order to ensure the security of the system,complex communication protocols and error detection techniques are used.The so-called communication protocol is a set of rules to ensure that the transmitted data is received and understood as the same as the transmitted data.

At present,two kinds of communication means are generally used in DCS system,namely synchronous and asynchronous.Synchronous communication relies on a clock signal to regulate data transmission and reception.Asynchronous network uses a reporting system without a clock.

FCS

There are three key points of FCS

(1)The core of FCS system is bus protocol,namely bus standard

As described in the previous chapter,once the bus protocol of a type of bus is determined,the relevant key technologies and related equipment will also be determined.As far as the basic principle of its bus protocol is concerned,all kinds of buses are the same,and the basic basis is to solve the bidirectional serial digital communication transmission.However,due to various reasons,the bus protocols of various buses are quite different.

In order to make the field bus meet the interoperability requirements and become a truly open system,the user layer of the IEC international standard and the field bus communication protocol model clearly stipulates that the user layer has the device description function.In order to achieve interoperability,each fieldbus device is described by device description DD.DD can be considered as a driver of the device,which includes all necessary parameter descriptions and operation steps required by the master station.Since DD includes all the information needed to describe the device communication and is independent of the master station,it can enable the field devices to achieve true interoperability.

Whether the actual situation is consistent with the above,the answer is no.At present,there are 8 types of fieldbus international standards,while the original IEO international standard is only one of the 8 types,which is equal to the other 7 types of buses.Each of the other seven bus protocols is supported by a set of software and hardware,regardless of their market share.They can form systems and products.The original IEC field bus international standard is an empty shelf without software support or hardware support.Therefore,it is almost impossible to realize the mutual compatibility and interoperability of these buses in the current state.

More...

| PLC-Module.com | XiongBa Industrial Control | Panda | DCS, PLC, FCS three systems comparison |